Ok here some more picks.

New engine unwrapped, very clean and only 79miles on the clock.

Old engine de-pipped and un-wired

old engine out and on the floor ready for strip down.

Oil filter and cooler assy removed.

Alternator and water pump removed.

Sump and manifolds off, just bear engine left.

These bits will go back on the new engine

New engine came with manifold for the donor golf.

removed

sump removed along with oil pump and pickup

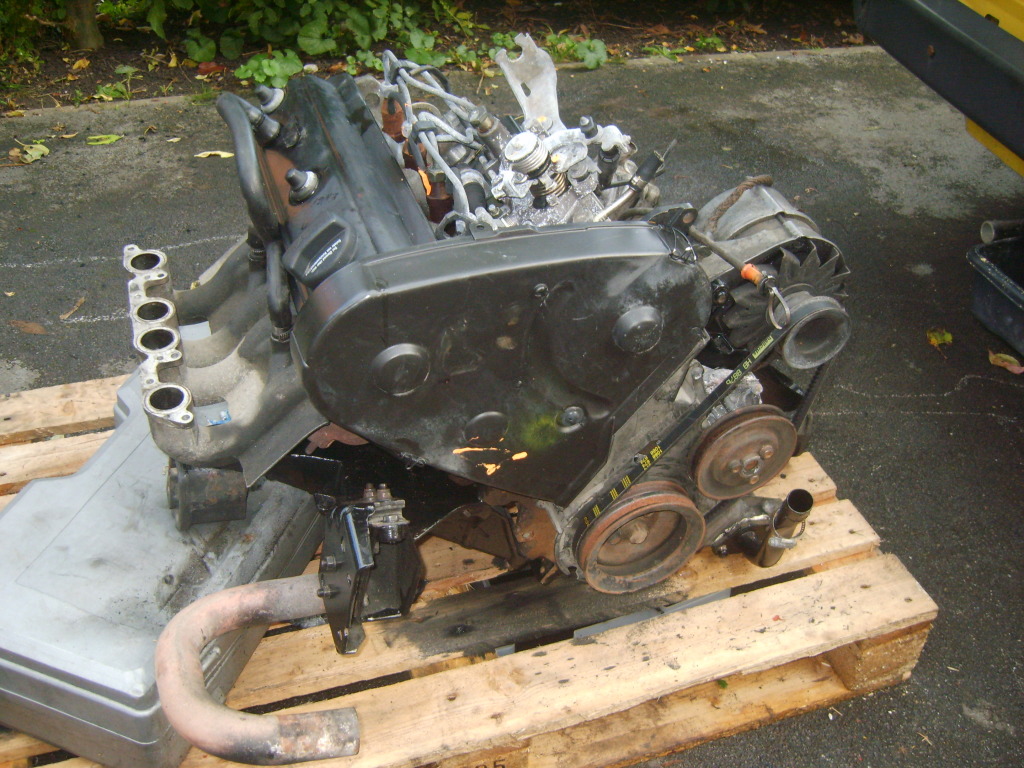

Flywheel clutch and engine mounts fitted

pulleys ,alternator bracket and alternator fitted, I used the original water pump as this sounded better than the one I rem0ved from the old engine.

I re used this cover because I had already modified it to clear pulleys and belts.

Engine now ready to go in. I haven't taken ant picks of this but I had to modify the dipstick tube because I snapt it when trying to remove it, however I successfully removed the one from the old engine, cut it about 15mm from the bottom of where it sits in the hole, bored it out to about 8mm but only 5 mm down and whilst it was hot put the longer dipstick tube in it and smeared the joint with sump sealant.

The idea is when it cools it makes a tight fit and the sealant was there as a secondary seal..... works a bute.

£ hour's later in the dark with the help of two friends using a trolly jack and scaff pole.... it in and ready to be plumed in.

This is all the unwanted bits left, If any one is interested in any of it let me know?

As the engine came with the same BOSH injector pump as the old one I decided to leave it in and mod it rather that swap it for the one that already modded and have to go through the stress of timing it up.

The mods were removing the immobilisers box with a hammer and chisel to get to the fuel cut off valve.

I have also repositioned the accelerator cable connection and cut off the excess metal with an angle grinder so that it will clear the lid.

I also wired the cold start solenoid with the fuel cut off so that it would reduce the revs over a short time instead of using the cable in the cab, Its just cable tied up so that it all else fails I can but it back to manual cold start.

Oh ass clenching moment when getting it in on Saturday night I could not turn the bottom pulley by hand even if I put all my wait on the ratchet so first thing that entered my head is the new engine is seased.

Left it for the morning with out much sleep worrying about it piped it and wired it, oiled and coolant in span it over with the starter motor and thank fuck it turned

To Be able to prime the pump, get oil pressure and water circulation I flattened the battery with in the first 15 minuets of turning it over.

So charged it for an hour and with the help of the works car and alot of turning over she sprung in to life.

Iv had a problem with cooling but I think it sorted now and the problem was with air in the system, The T3 uses 16 liters of coolant with a 50/50 mix of antifreez oh and I have replaced the 87deg thermostat with a 80 witch worked fine on the old engine.